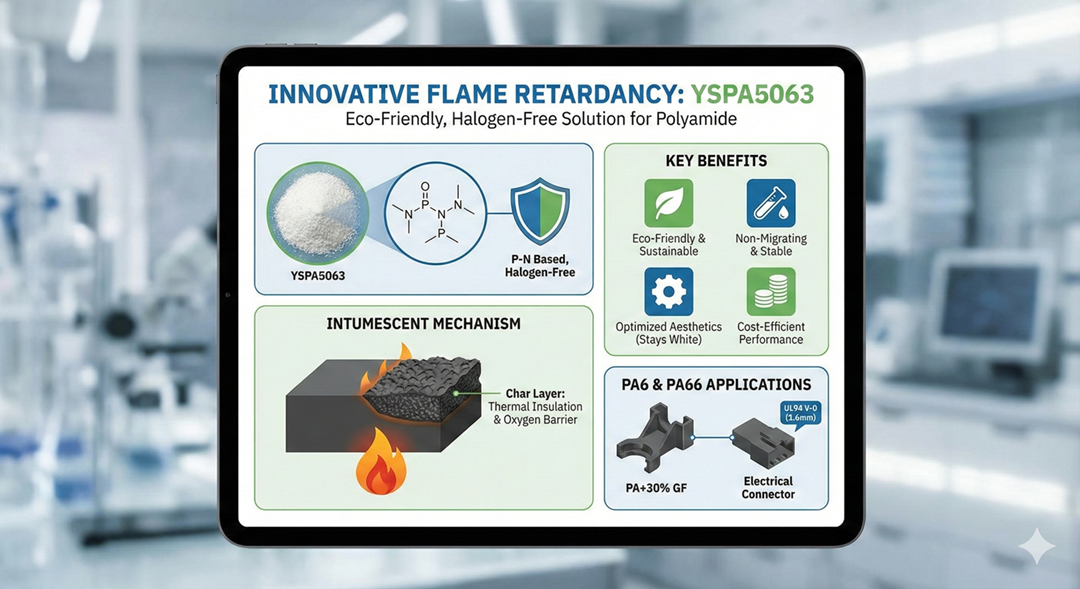

We are pleased to introduce YSPA5063, a high-efficiency, Phosphorus-Nitrogen (P-N) based halogen-free flame retardant. Specifically engineered for Polyamide (PA), this eco-friendly formulation is optimized for both glass fiber (GF) reinforced and non-reinforced nylon, delivering a superior cost-performance ratio compared to traditional bromine-antimony systems.

Advanced Synergistic Protection

YSPA5063 utilizes a highly effective synergistic mechanism. During combustion, it facilitates the formation of a dense intumescent char layer. This layer serves multiple protective functions:

-

Thermal Insulation: Protects the underlying polymer from heat.

-

Oxygen Barrier: Starves the flame of the oxygen required for combustion.

-

Flame Suppression: Effectively prevents the spread of fire and ensures excellent self-extinguishing properties.

Key Benefits

-

Exceptional Stability: Non-hydrolyzing, non-precipitating, and non-migrating, ensuring long-term performance and material integrity.

-

Optimized Aesthetics: Finished injection-molded parts remain white and do not suffer from greying.

-

High Thermal Resistance: With a decomposition temperature exceeding $350^{\circ}C$, it withstands the rigorous processing temperatures required for engineering plastics.

-

Superior Processing: Designed to prevent common manufacturing issues such as strand breakage, foaming, or drooling.

Superior Efficiency: YSPA5063 vs. Traditional Bromine-Antimony Systems

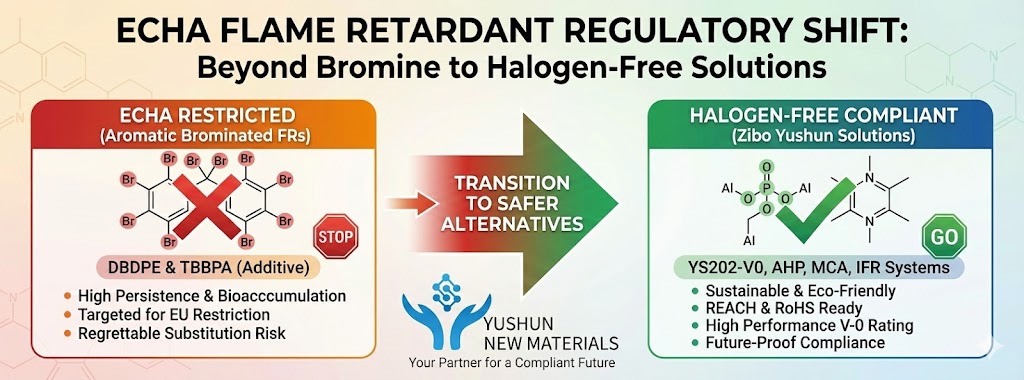

While Bromine-Antimony (Br-Sb) systems have long been the industry standard for flame retardancy, YSPA5063 offers a modern, high-performance alternative specifically optimized for Polyamide (PA). By utilizing a synergistic Phosphorus-Nitrogen (P-N) mechanism, YSPA5063 achieves equivalent fire safety ratings while providing significant advantages in environmental impact and material longevity.

| Feature | YSPA5063 (P-N System) | Traditional Bromine-Antimony |

| Mechanism |

Intumescent char formation (insulates & blocks oxygen). |

Gas-phase radical scavenging (interrupts combustion). |

| Environmental Impact |

Halogen-Free & Eco-Friendly: Meets strict global environmental regulations. |

Contains halogens; may release toxic/corrosive gases during combustion. |

| Material Migration |

Non-migrating & Non-precipitating: Ensures long-term stable performance. |

Prone to blooming (migration to the surface) over time. |

| Stability |

Non-hydrolyzing: Maintains properties even in humid conditions. |

Can be sensitive to moisture, potentially degrading mechanical properties. |

| Aesthetics |

Excellent Whiteness (>95): Molded parts stay white and do not turn grey. |

Often causes yellowing or darkening of the base polymer. |

| Electrical Properties |

High CTI (600V): Ideal for high-voltage electrical components. |

Generally results in lower Comparative Tracking Index (CTI) values. |