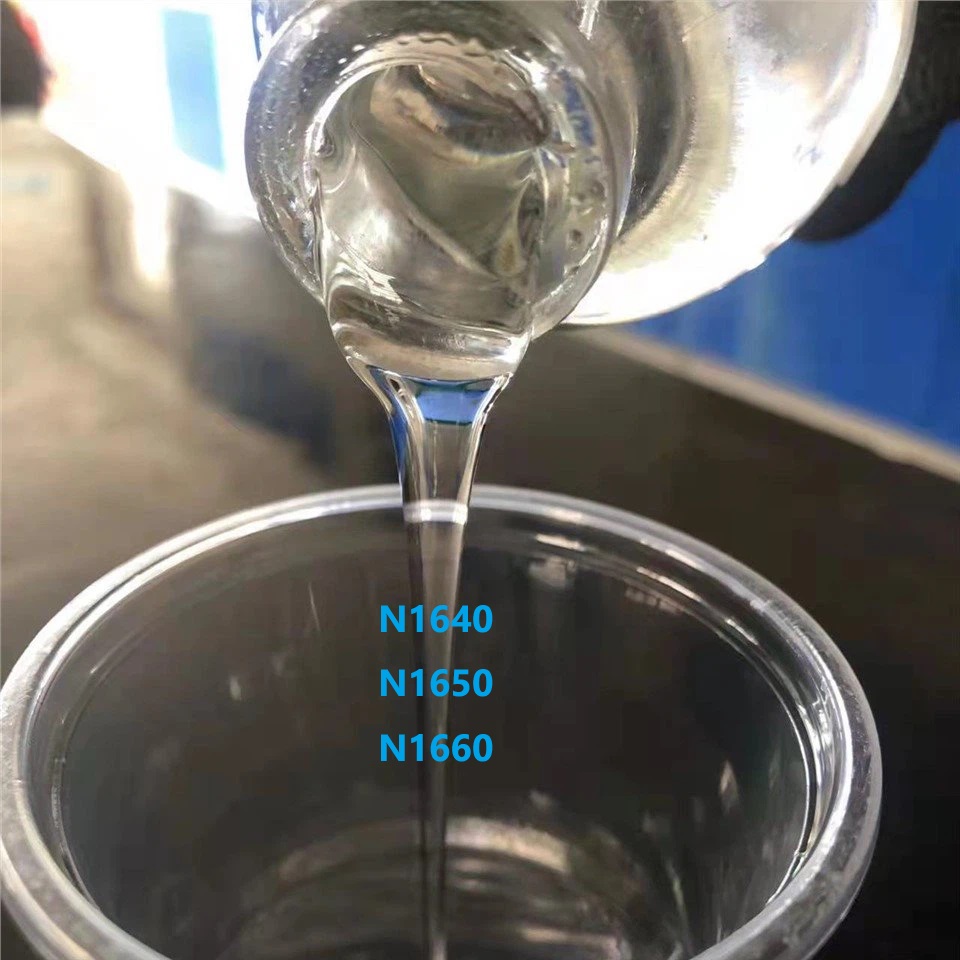

Solvent-Resistant Prepolymers

Index | N1640 | N1650 | N1660 |

NCO Content (%) | 3.3 | 4.0 | 4.0 |

Operating Conditions | |||

Ratio (Poly: BDO) | 100:12.5 | 100:15 | 100:7.45 |

Prepolymer Temp (°C) | 80-85 | 80-85 | 80-85 |

Curing Agent Temp (°C) | 60-70 | 60-70 | 60-70 |

Mold Temp (°C) | 100-105 | 100-105 | 100-105 |

Pot Life (min) | 120 | 40 | 30 |

After Cure (h/100°C) | 16-20 | 16-20 | 16-20 |

Physical Performance | |||

Shore Hardness (A) | 40-44 | 50-54 | 62-64 |

Ultimate Elongation (%) | 468 | 366 | 302 |

Tensile Strength (MPa) | 2 | 5 | 8 |

Tear Strength (without Nick) (KN/m) | 8 | 16 | 22 |

Resilience (%) | 47 | 27 | 21 |

Density (25℃) (g/cm³) | 1.24 | 1.257 | 1.245 |

Solvent-Resistant Prepolymers are specialized polyurethane prepolymers designed to withstand exposure to harsh chemicals, including solvents, oils, fuels, and other aggressive substances, without degrading or losing their mechanical properties. These prepolymers are often formulated using isocyanates like MDI (Methylene Diphenyl Diisocyanate) or TDI (Toluene Diisocyanate), combined with polyols such as Polyester or Polyether that enhance chemical resistance. Solvent-resistant prepolymers are crucial in environments where chemical exposure is frequent and materials need to maintain durability, flexibility, and performance under harsh conditions.

Key Features:

· High Chemical Resistance: They resist breakdown or softening when exposed to organic solvents, fuels, oils, and other corrosive chemicals.

· Mechanical Strength: These prepolymers retain their mechanical integrity, offering excellent tensile strength, tear resistance, and toughness even in solvent-rich environments.

· Hydrolytic Stability: Many solvent-resistant prepolymers also offer resistance to moisture and water, making them ideal for environments where both chemicals and water are present.

Applications of Solvent-Resistant Prepolymers:

1. Seals and Gaskets: Used in industries such as automotive, oil and gas, and chemical processing, where components are exposed to oils, fuels, and other harsh chemicals.

2. Industrial Hoses and Tubing: Essential for transporting aggressive chemicals, fuels, or oils, solvent-resistant prepolymers ensure durability and long service life.

3. Coatings: Applied as protective layers in environments exposed to solvents, oils, and corrosive chemicals, such as pipelines, tanks, and machinery.

4. Adhesives: Used in bonding applications where chemical exposure is common, such as automotive, aerospace, and industrial equipment.

5. Wheels and Rollers: Found in industrial applications where contact with chemicals or solvents is routine, such as chemical processing plants and refineries.

In summary, Solvent-Resistant Prepolymers provide excellent chemical resistance and mechanical strength in applications where contact with aggressive solvents, fuels, and oils is common, ensuring long-term performance and reliability in challenging industrial environments.