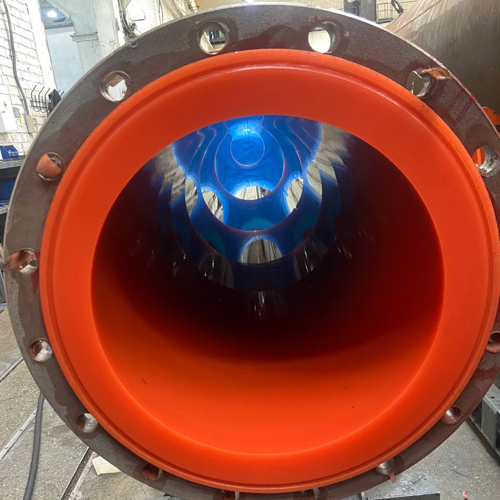

PU Lining

Polyurethane (PU) lining is a protective coating applied to the inner surfaces of pipelines. This lining helps improve the longevity, durability, and performance of the pipeline by providing a layer of protection against corrosion, abrasion, and chemical attacks. PU linings are highly elastic, flexible, and resistant to a wide range of chemicals, making them suitable for use in industries where pipelines transport abrasive materials, fluids, or chemicals.

Function of PU Lining Inside Pipelines:

1. Abrasion Resistance: PU linings protect the internal surface of pipelines from wear caused by abrasive materials. This is particularly important in industries where solid particles are transported, such as in mining, slurry transport, and wastewater systems.

2. Corrosion Protection: By preventing direct contact between the transported material and the pipe material, PU linings act as a barrier against corrosion. This is crucial for pipelines carrying corrosive liquids, chemicals, or gases.

3. Improved Flow Efficiency: The smooth surface of PU linings reduces friction inside the pipe, allowing for improved flow rates and reducing the energy required to pump materials through the pipeline.

4. Chemical Resistance: PU is highly resistant to many chemicals, making the lining suitable for industries where aggressive chemicals are transported, such as chemical processing, oil and gas, and food processing industries.

5. Waterproofing: The polyurethane coating forms a waterproof layer, preventing leaks and water ingress, which is particularly useful in pipelines that transport fluids or operate in humid or wet environments.

6. Temperature Resistance: PU linings can withstand a wide range of temperatures, protecting pipelines from damage caused by temperature fluctuations or extreme heat/cold, depending on the specific polyurethane formulation.

Applications:

· Mining and Slurry Pipelines: To protect against the abrasive nature of materials being transported, such as coal, ore, and sand.

· Wastewater Treatment: PU linings prevent corrosion from the chemicals present in wastewater and sludge.

· Oil and Gas Pipelines: These linings provide corrosion protection for pipes used in transporting crude oil, natural gas, and other petrochemicals.

· Chemical Processing: In chemical plants, PU linings safeguard pipes from corrosive chemicals and fluids.

· Food and Beverage Industry: They are used for pipelines in food processing plants where hygiene and chemical resistance are critical.

PU linings significantly extend the operational life of pipelines while reducing maintenance and repair costs. Their versatility and resistance to harsh conditions make them essential in many industrial sectors.